Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

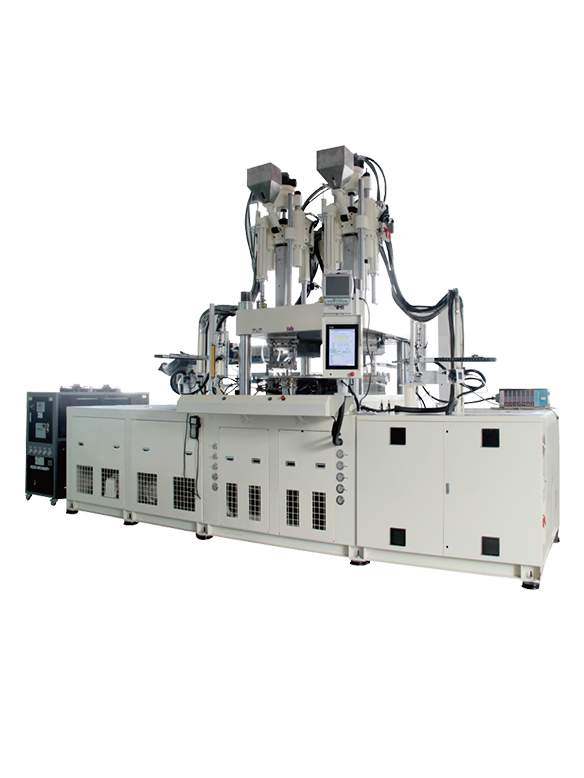

Featuring vertical clamping and vertical injection with two sets of center rotary tower systems and two sets of rotary table systems, the L series three-color injection molding machine has three upper platens and six down platens, making it a comprehensive solution provider for vertical injection molding machines. The LZ-SL series three-color injection molding machine is equipped with two sets of center rotary tower systems, two sets of rotary table systems, and a control system developed in conjunction with vertical injection molding machines, enabling the production of three-color handle products. The injection mechanism can be matched with the appropriate size according to the product requirements. Product options include a servo energy-saving system, electric injection system, and high-speed injection system.

Featuring vertical clamping and vertical injection with two sets of center rotary tower systems and two sets of rotary table systems, the L series three-color injection molding machine has three upper molds and six lower molds, making it a comprehensive solution provider for vertical injection molding machines.

Clamping force: 120-1000 tons

Injection volume: 0-3000 grams

The LZ-SL series three-color injection molding machine is equipped with two sets of center rotary tower systems, two sets of rotary table systems, and a control system developed in conjunction with vertical injection molding machines, enabling the production of three-color handle products. The injection mechanism can be matched with the appropriate size according to the product requirements.

Product options include a servo energy-saving system, electric injection system, and high-speed injection system. The options for a servo energy-saving system, electric injection system, and high-speed injection system provide additional customization options for the machine.

Telephone Consultation

Wechat Consulting

Online Message